Start a project

CNC Milling Services

Our precision CNC machining services achieve tolerances up to ±0.01mm, with prototypes delivered in as fast as three days.

Backed by 15 years of experience in 3-axis to 5-axis CNC machining, we provide customized solutions tailored to our customers' needs.

-

Machined prototypes in as fast as 1 days.

-

50+metals and plastics.

-

Tolerances down to +-0.001mm.

-

ISO 9001:2015 to ensure high-level and precision parts.

Start your CNC Milling project

Upload your design files and get a professional online CNC quote within 2 hours.

STEP,STP, IGS, PRT, sldprt, sat, x_t

Maximum file size: 20MB.

All uploads are secure and confidential.

Understand CNC

What is CNC Milling?

CNC milling is a precise and versatile machining process where material is removed using computer-controlled machines to create complex parts.

This technology is widely used across industries like aerospace, automotive, and electronics to produce high-quality components with intricate shapes and tight tolerances.

By utilizing G-code, a standardized programming language, CNC machining ensures repeatable and efficient production, significantly enhancing productivity. Its versatility and precision make it an indispensable tool in industries where complex and precise manufacturing is essential.

Our CNC Milling Capabilities

3-Axis, 4-Axis, and 5-Axis Machining

Precise and efficient 3-5 axis CNC machining to meet the demands of complex and Precision CNC parts manufacturing.

We efficiently handle a wide range of geometries and part sizes while maintaining high dimensional accuracy and fast turnaround times.

Our Precision 3 axis CNC mills provide high precision for components with prismatic features, typically achieving tolerances of ±0.05mm, with capability down to ±0.02mm for select applications

Our 4 axis CNC lathes are equipped with live tooling, enabling efficient machining of complex rotational parts. Most intricate features can be completed in a single setup without the need for secondary operations, significantly improving both precision and efficiency.

Our advanced 5-axis machining centers can complete complex multi-surface machining in a single setup. The machining tolerance is typically ±0.05 mm, and for certain precision applications, it can be as tight as ±0.01 mm.

Visit Equipment

Our Factory

Our CNC factory uses precision machines to carve and shape parts with high accuracy, ensuring top-quality results for your projects.

CNC Machining Materials

We offer access to a large range of production-grade plastic and metal materials ready to be machined.

Below is a non-exhaustive list of the most common plastic and metal material used for CNC prototyping.

Aluminum

Lightweight yet strong, aluminum is the ideal choice for components requiring high strength-to-weight ratios. Its excellent machinability, corrosion resistance, and versatility make it perfect for industries like aerospace, automotive, and electronics

Subtypes:Aluminum 6061, 6061-T6, Aluminum 2024, Aluminum 5052, Aluminum 5083, Aluminum 6063, Aluminum 6082, Aluminum 7075, 7075-T6, Aluminum ADC12 (A380)

Magnesium

Magnesium, as the lightest structural metal, combines high machinability with strength. It’s a favorite for applications requiring weight reduction, like automotive and aerospace parts, without compromising performance.

Subtypes:Magnesium Alloy AZ31, AZ61, AZ91, and AZ92

Invar

Invar is a nickel-iron alloy with extremely low thermal expansion, ideal for precision instruments, clocks, aerospace components, and applications requiring dimensional stability under temperature changes.

Subtypes:Alloy49

Brass

Brass offers excellent machinability, a strong strength-to-weight ratio, corrosion resistance, and high conductivity, making it ideal for industrial applications requiring durability and precision.

Subtypes:Brass C260, C268, C272, C280, C360, C464, C485, Naval Brass, Free-cutting Brass, High-strength Brass

Copper

Copper stands out with its superior electrical and thermal conductivity. It’s the go-to material for electrical components, heat exchangers, and industrial applications where precision is key.

Subtypes:Copper C101(T2), Copper C103(T1), Copper C103(TU2), Copper C110(TU0), Beryllium Copper

Stainless Steel

Stainless steel offers excellent corrosion resistance, durability, and a polished finish, making it suitable for medical instruments, food processing equipment, and architectural applications.

Subtypes:Stainless Steel SUS201, SUS303, SUS 304, SUS316, SUS316L, SUS42, SUS430, SUS431, SUS440C, SUS630/17-4PH, AISI 304

Steel

Stainless steel is a corrosion-resistant alloy of steel, chromium, and nickel. It’s ideal for kitchen appliances, medical equipment, and automotive parts.

Subtypes:Steel 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140, A36, Die steel, Alloy steel, Chisel tool steel, Spring steel, High speed steel, Cold rolled steel, Bearing steel, SPCC

Titanium

Titanium’s unmatched strength and corrosion resistance make it indispensable in demanding industries such as aerospace, medical devices, and marine engineering. Its biocompatibility also ensures reliability in surgical applications.

Subtypes:Titanium Alloy TA1, Alloy TA2, Alloy TC4/Ti-6Al 4V

Zinc

Zinc is a corrosion-resistant metal often used for galvanizing steel, die casting, and making batteries, automotive parts, and hardware due to its durability and low cost.

Subtypes:Zamak 3 , Zamak 5 , ZA-8

CNC Machining Finishings

There are numerous finishing options available in CNC machining.

These finishing processes involve machine or hand processing, and can improve the appearance, functionality, and durability of the part.

| Surface Finish | Color | Description | Materials |

|---|---|---|---|

As-Machined

As-Machined |

N/A | Parts are left with visible tool marks from the machining process. | Metals, Plastics |

Anodizing

Anodizing |

Clear, Black, Custom | Electrochemical process that adds a corrosion-resistant oxide layer. | Aluminum |

Sand Blasting

Sand Blasting |

Matte Gray | Creates a smooth, matte texture by blasting the surface with abrasives. | Metals, Plastics |

Powder Coating

Powder Coating |

Custom Colors | Durable, uniform color coating applied via electrostatic spraying. | Metals |

Electropolishing

Electropolishing |

Shiny Metal | Electrochemical polishing for a smooth, bright finish with reduced roughness. | Stainless Steel, Aluminum |

Brushing

Brushing |

Metallic | Satin finish with visible brush marks that create a uniform grain. | Metals |

Polishing

Polishing |

High Gloss | Buffing process that produces a mirror-like, reflective finish. | Metals, Plastics |

Electroplating

Electroplating |

Silver, Gold, Nickel | Adds a thin layer of another metal for enhanced durability and appearance. | Steel, Copper, Brass |

Black Oxide

Black Oxide |

Black | Dark, mild corrosion-resistant coating for steel and stainless steel. | Steel, Stainless Steel |

Passivation

Passivation |

N/A | Chemical treatment that improves corrosion resistance, particularly for stainless steel. | Stainless Steel |

Heat Treatment

Heat Treatment |

N/A | Controlled heating and cooling process to modify material properties like hardness. | Steel, Aluminum, Titanium |

CNC Milling Tolerances and Accuracy

We can typically achieve the following standards, while more complex applications will need to be evaluated by our engineers.

| Category | 3-Axis CNC Milling | 4-Axis CNC Milling | 5-Axis CNC Milling |

|---|---|---|---|

| Positioning Accuracy | ±0.05 mm ~ ±0.025 mm | ±0.05 mm ~ ±0.025 mm | ±0.01 mm ~ ±0.008 mm |

| Repeatability | ±0.025 mm ~ ±0.01 mm | ±0.025 mm ~ ±0.01 mm | ±0.005 mm ~ ±0.008 mm |

| CNC Milling Tolerances | 0.125 mm ~ ±0.025 mm | 0.125 mm ~ ±0.025 mm | 0.025 mm ~ ±0.01 mm |

| Size Range | ≤ 1524 mm × 1016 mm × 508 mm (60" × 40" × 20") |

≤ 1524 mm × 1016 mm × 508 mm (60" × 40" × 20") |

≤ 1524 mm × 1016 mm × 508 mm (60" × 40" × 20") |

| Machinable Surfaces | Single setup, XYZ only | Added rotation axis for angled features | Full-surface multi-axis machining |

| Typical Applications | Flat parts, outer contours | Angled holes, curves, engraving | Complex surfaces, high-precision molds |

Check out our cases

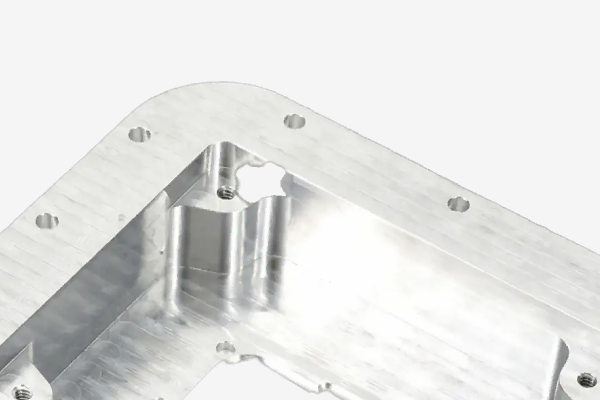

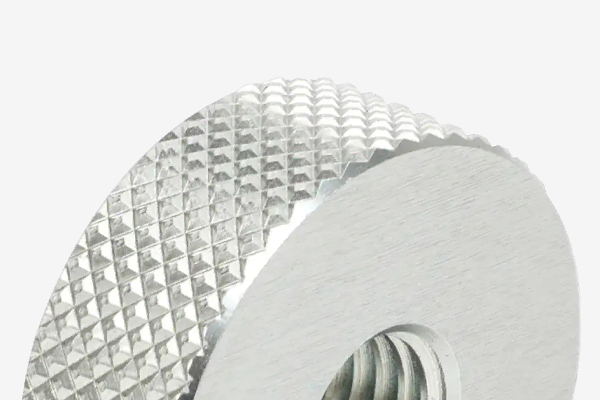

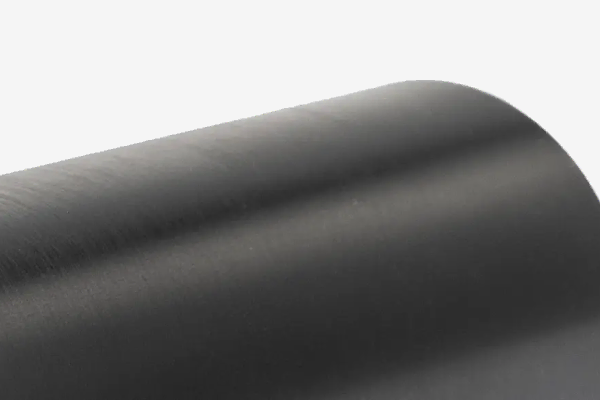

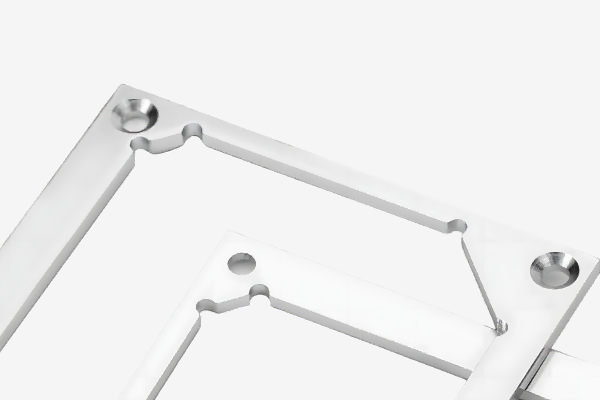

CNC Machined Parts Gallery

Explore our precision-machined components for various industries and discover innovative designs and craftsmanship that might meet your manufacturing needs.

CNC Milling FAQ

FAQs and Solutions

provides CNC machining solutions for a variety of industries. Whether it’s durable consumer products, complex electronics, industrial machinery, or medical devices, we deliver reliable and precise components tailored to your needs.

If you have any questions about the task, please feel free to contact us.

Our experienced engineers will respond to you within 1-24 hours

CNC(Computer Numerical Control) milling machines process parts by securing the material or workpiece to the machine bed. A high-speed spindle holds the cutting tool to remove material. The spindle and bed move horizontally and vertically to adjust the workpiece's position, enabling precise cuts of different shapes and depths. Machines with multi-axes allow the tool to reach various surfaces and complex areas, reducing programme setups.

CNC machining is an excellent choice for prototyping due to its speed, precision, and versatility. It allows for rapid and accurate creation of prototypes, accommodates various materials, handles complex designs, and supports quick iterations, making it a top choice for turning ideas into tangible proof-of-concept models.

CNC machining is a great choice for prototyping, offering a range of advantages depending on the specific requirements. Notably, it excels in high precision, accommodates both small and large-scale production, provides rapid results, and is versatile in handling intricate designs.

CNC machining indeed provides high levels of accuracy. It’s possibly the most accurate among our production methods, achieving precision up to +/- 0.004 in or 0.01 mm.

Our custom CNC milling services are priced based on each customer’s project,which already ensures the most cost-effective solution. In today’s era of price transparency, our tailored services remain among the most competitive in the industry. If someone offers you a lower price, it inevitably means they have compromised on quality control.