Start a project

Sheet Metal Services

Great Jump custom sheet metal prototyping services offer a fast and cost-effective solution for your projects. Services including bending, punching, cutting standard gauge metal for both prototypes and low volume production runs.

Sheet metal fabrication produces durable, end-use metal parts with a wide selection of materials and finishes that meet your specifications, for a variety of industries like: Automotive, Medical device, Aerospace, electronics, energy and robotics.

-

Fast Samples: Ready in 3 days, efficient production.

-

High Precision: Tolerance to ±0.1 mm.

-

Full Processes: Cutting, bending, welding, and more.

-

Flexible Production: Low or high volumes.

-

Certified Quality: ISO-standard results.

Start your Sheet Metal project

Upload your design files and get a professional online quote within 2 hours.

STEP,STP, IGS, PRT, sldprt, sat, x_t

Maximum file size: 20MB.

All uploads are secure and confidential.

Understand Sheet Metal

What is Sheet Metal Fabrication?

Sheet metal fabrication is a versatile manufacturing process that involves transforming flat metal sheets into a wide range of products and components.

This process typically includes several key steps such as cutting, bending, and assembling the metal sheets to create the desired shapes and structures. It is widely used across various industries, including automotive, aerospace, electronics, and construction, due to its ability to produce durable, high-precision parts and products.

The materials used can vary from steel and aluminum to stainless steel, depending on the specific requirements of the application. Sheet metal fabrication is essential for creating everything from small parts like brackets and enclosures to large structures like building frameworks and vehicle bodies.

What can we do

Our Sheet Metal Solutions

Years of experience in sheet metal production and processing,

a professional design team and a large processing equipment group provide you with a one-stop solution for sheet metal processing.

Laser cutting is a subtractive manufacturing process that uses a high-powered and focused laser beam to create precise cuts in sheet metal materials.

Press brake forming uses a matching punch and die set and the application of force along a straight axis, producing linear bends on metal sheets.

High-speed stamping delivers durable, intricately shaped parts at scale. This process is ideal for mass production of lightweight yet strong components with uniform quality.

We provide TIG, MIG, and spot welding for seamless and strong metal joints. Welding is perfect for structural assemblies, ensuring durability and clean finishes for both visible and functional parts.

Visit Equipment

Our Factory

Our CNC factory uses precision machines to carve and shape parts with high accuracy, ensuring top-quality results for your projects.

Sheet metal materials

We offer a wide range of metal materials such as aluminum, steel, stainless steel, brass, and copper,

for customizing your prototype and low-volume production profiles using sheet metal.

Stainless steel sheet

Stainless steel sheet offers excellent corrosion resistance, strength, and durability, commonly used in automotive, construction, and industrial applications for precision fabrication.

Cold-rolled steel sheet

Cold-rolled steel is produced by rolling steel at room temperature, offering enhanced surface finish, strength, and precision. It’s widely used in automotive, appliances, and construction.

Aluminum

Aluminum sheet is lightweight, corrosion-resistant, and versatile. Used in automotive, aerospace, and construction, it’s ideal for applications requiring durability and formability.

Hot-dip galvanized steel sheet

Hot-dip galvanized steel sheet is coated with zinc for enhanced corrosion resistance, widely used in construction, automotive, and outdoor applications requiring durability.

Hot-rolled steel sheet

Hot-rolled steel sheet is produced by heating steel to above its recrystallization temperature, then rolling it into desired thickness. It’s commonly used in construction and heavy machinery.

Copper Plate

Copper plate is a highly conductive material known for its excellent corrosion resistance and electrical properties, commonly used in electrical applications and heat exchangers.

CNC Machining Finishings

There are numerous finishing options available in CNC machining.

These finishing processes involve machine or hand processing, and can improve the appearance, functionality, and durability of the part.

| Surface Finish | Color | Description | Materials |

|---|---|---|---|

Standard

Standard |

Natural Metal | The raw finish is directly after fabrication. | All Metals |

Anodizing

Anodizing |

Clear, Black, Custom | Electrochemical process that adds a corrosion-resistant oxide layer. | Aluminum |

Sand Blasting

Sand Blasting |

Matte Gray | Creates a smooth, matte texture by blasting the surface with abrasives. | Metals, Plastics |

Powder Coating

Powder Coating |

Custom Colors | Durable, uniform color coating applied via electrostatic spraying. | Metals |

Polishing

Polishing |

High Gloss | Buffing process that produces a mirror-like, reflective finish. | Metals, Plastics |

Electroplating

Electroplating |

Silver, Gold, Nickel | Adds a thin layer of another metal for enhanced durability and appearance. | Steel, Copper, Brass |

CNC Turning Tolerance

We have multiple CNC manufacturing capabilities and can meet any specific custom CNC turning machining needs.

| Process | Thickness Range | Accuracy Requirements | Applicable Equipment |

|---|---|---|---|

| Laser Cutting | 0.5mm - 20mm | Accuracy ±0.1mm - ±0.2mm | Laser Cutting Machine |

| Punching/Stamping | 0.5mm - 10mm | Accuracy ±0.2mm | Punching Machine |

| NC Bending | 0.5mm - 10mm | Accuracy ±0.2mm - ±0.5mm | NC Bending Machine |

| Spray Sandblasting | All Metal Materials | - | Sandblasting Machine |

| Coating/Painting | All Metal Materials | - | Spray Coating Equipment |

Check out our cases

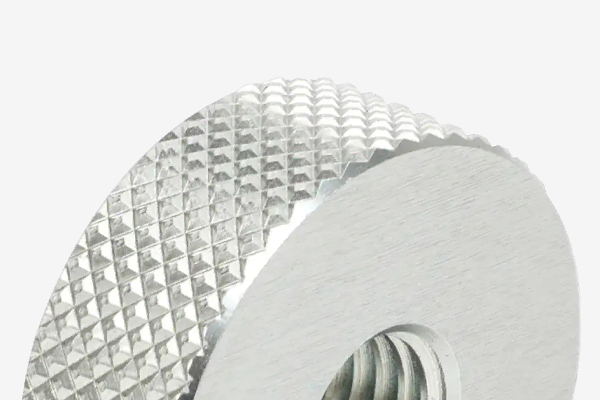

Sheet Metal Parts Gallery

Explore our components for various industries and discover innovative designs and craftsmanship that might meet your manufacturing needs.

Sheet Metal FAQ

FAQs and Solutions

We provides machining solutions for a variety of industries. Whether it’s durable consumer products, complex electronics, industrial machinery, or medical devices, we deliver reliable and precise components tailored to your needs.

If you have any questions about the task, please feel free to contact us.

Our experienced engineers will respond to you within 1-24 hours

We handle stainless steel, aluminum, carbon steel, copper, and more.

Our capabilities range from 0.5 mm to 20 mm in thickness, with maximum dimensions of 3000 × 1500 mm.

Yes, we offer flexible production options, from prototypes to large-scale manufacturing.

Samples are ready within 3 days, while bulk orders typically take 7-15 days, depending on complexity.

Yes, we offer powder coating, anodizing, polishing, brushing, and more.

Upload your design files or share your requirements, and our engineers will provide a detailed quote within 3 hours.