Start a project

CNC Turning Services

Great Jump specializes in precision CNC turning, delivering custom parts with tight tolerances and superior surface finishes.

From prototypes to high-volume production, we meet diverse industry requirements with unmatched efficiency and accuracy.

-

15+ years experience in machining metal parts.

-

Advanced equipment & professional testing, quality assurance.

-

Digital management process, amazing efficiency.

-

Tolerances down to +-0.001mm.

-

ISO 9001:2015 to ensure high-level and precision parts.

Start your CNC Turning project

Upload your design files and get a professional online CNC quote within 2 hours.

STEP,STP, IGS, PRT, sldprt, sat, x_t

Maximum file size: 20MB.

All uploads are secure and confidential.

Understand CNC

What is CNC Turning?

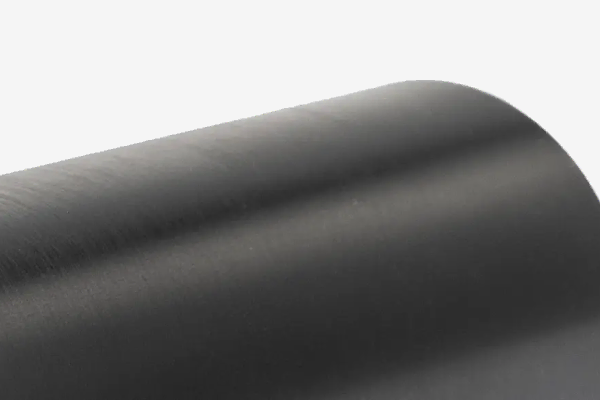

CNC turning is a subtractive manufacturing process where a cutting tool removes material from a rotating workpiece to produce cylindrical shapes or intricate designs.

Guided by computer-aided design (CAD), this process ensures precision, efficiency, and consistency, making it ideal for creating components like shafts, bushings, and fasteners.

Turned parts can then be left as-machined, with visible tool marks, or bead blasted. When the run is complete, parts are inspected, boxed and shipped shortly thereafter.

What can we do

Our CNC Turning Solutions

Great Jump is capable to provide cost-effective CNC turning lathe services and quality products with high precision and accuracy for vast projects.

Visit Equipment

Our Factory

Our CNC factory uses precision machines to carve and shape parts with high accuracy, ensuring top-quality results for your projects.

CNC Machining Materials

We provide high-quality metals, plastics, and composite materials for CNC machining,

capable of meeting a wide variety of application requirements, including but not limited to:

Aluminum

Lightweight yet strong, aluminum is the ideal choice for components requiring high strength-to-weight ratios. Its excellent machinability, corrosion resistance, and versatility make it perfect for industries like aerospace, automotive, and electronics

Subtypes:Aluminum 6061, 6061-T6, Aluminum 2024, Aluminum 5052, Aluminum 5083, Aluminum 6063, Aluminum 6082, Aluminum 7075, 7075-T6, Aluminum ADC12 (A380)

Magnesium

Magnesium, as the lightest structural metal, combines high machinability with strength. It’s a favorite for applications requiring weight reduction, like automotive and aerospace parts, without compromising performance.

Subtypes:Magnesium Alloy AZ31, AZ61, AZ91, and AZ92

Invar

Invar is a nickel-iron alloy with extremely low thermal expansion, ideal for precision instruments, clocks, aerospace components, and applications requiring dimensional stability under temperature changes.

Subtypes:Alloy49

Brass

Brass offers excellent machinability, a strong strength-to-weight ratio, corrosion resistance, and high conductivity, making it ideal for industrial applications requiring durability and precision.

Subtypes:Brass C260, C268, C272, C280, C360, C464, C485, Naval Brass, Free-cutting Brass, High-strength Brass

Copper

Copper stands out with its superior electrical and thermal conductivity. It’s the go-to material for electrical components, heat exchangers, and industrial applications where precision is key.

Subtypes:Copper C101(T2), Copper C103(T1), Copper C103(TU2), Copper C110(TU0), Beryllium Copper

Stainless Steel

Stainless steel offers excellent corrosion resistance, durability, and a polished finish, making it suitable for medical instruments, food processing equipment, and architectural applications.

Subtypes:Stainless Steel SUS201, SUS303, SUS 304, SUS316, SUS316L, SUS42, SUS430, SUS431, SUS440C, SUS630/17-4PH, AISI 304

Steel

Stainless steel is a corrosion-resistant alloy of steel, chromium, and nickel. It’s ideal for kitchen appliances, medical equipment, and automotive parts.

Subtypes:Steel 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140, A36, Die steel, Alloy steel, Chisel tool steel, Spring steel, High speed steel, Cold rolled steel, Bearing steel, SPCC

Titanium

Titanium’s unmatched strength and corrosion resistance make it indispensable in demanding industries such as aerospace, medical devices, and marine engineering. Its biocompatibility also ensures reliability in surgical applications.

Subtypes:Titanium Alloy TA1, Alloy TA2, Alloy TC4/Ti-6Al 4V

Zinc

Zinc is a corrosion-resistant metal often used for galvanizing steel, die casting, and making batteries, automotive parts, and hardware due to its durability and low cost.

Subtypes:Zamak 3 , Zamak 5 , ZA-8

CNC Machining Finishings

There are numerous finishing options available in CNC machining.

These finishing processes involve machine or hand processing, and can improve the appearance, functionality, and durability of the part.

W| Surface Finish | Color | Description | Materials |

|---|---|---|---|

As-Machined

As-Machined |

N/A | Parts are left with visible tool marks from the machining process. | Metals, Plastics |

Anodizing

Anodizing |

Clear, Black, Custom | Electrochemical process that adds a corrosion-resistant oxide layer. | Aluminum |

Sand Blasting

Sand Blasting |

Matte Gray | Creates a smooth, matte texture by blasting the surface with abrasives. | Metals, Plastics |

Powder Coating

Powder Coating |

Custom Colors | Durable, uniform color coating applied via electrostatic spraying. | Metals |

Electropolishing

Electropolishing |

Shiny Metal | Electrochemical polishing for a smooth, bright finish with reduced roughness. | Stainless Steel, Aluminum |

Brushing

Brushing |

Metallic | Satin finish with visible brush marks that create a uniform grain. | Metals |

Polishing

Polishing |

High Gloss | Buffing process that produces a mirror-like, reflective finish. | Metals, Plastics |

Electroplating

Electroplating |

Silver, Gold, Nickel | Adds a thin layer of another metal for enhanced durability and appearance. | Steel, Copper, Brass |

Black Oxide

Black Oxide |

Black | Dark, mild corrosion-resistant coating for steel and stainless steel. | Steel, Stainless Steel |

Passivation

Passivation |

N/A | Chemical treatment that improves corrosion resistance, particularly for stainless steel. | Stainless Steel |

Heat Treatment

Heat Treatment |

N/A | Controlled heating and cooling process to modify material properties like hardness. | Steel, Aluminum, Titanium |

CNC Turning Tolerance

We have multiple CNC manufacturing capabilities and can meet any specific custom CNC turning machining needs.

| Category | Details |

|---|---|

| Threaded Holes |

- UNC & UNF threads: From #2 up to 0.5 in. - Metric threads: M1.2 and above |

| Radii | Turned outside corners will typically include a 0.005 in. chamfer. |

| Minimum Hole Size |

- Minimum on-axis and axial: 0.04 in. (1mm) - Minimum radial: 0.08 in. (0.5mm); 0.04 in. (0.5mm) for aluminum and brass |

| Grooves |

- Minimum OD groove width: 0.047 in. (1.2mm) - Minimum OD groove width for aluminum and brass: 0.019 in. (0.5mm) - Maximum OD groove depth: 0.95 in. (24.1mm) — varies with groove width |

| Linear Dimension |

- ± 0.025mm - ± 0.001 inches |

| Hole Diameter (not reamed) |

- ± 0.025mm - ± 0.001 inches |

| Shaft Diameter |

- ± 0.025mm - ± 0.001 inches |

| Part Dimension Limit |

- 950*550*480mm - 37.0 * 21.5 * 18.5 inches |

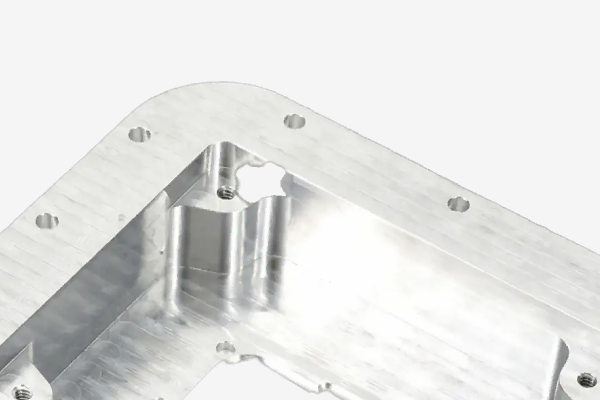

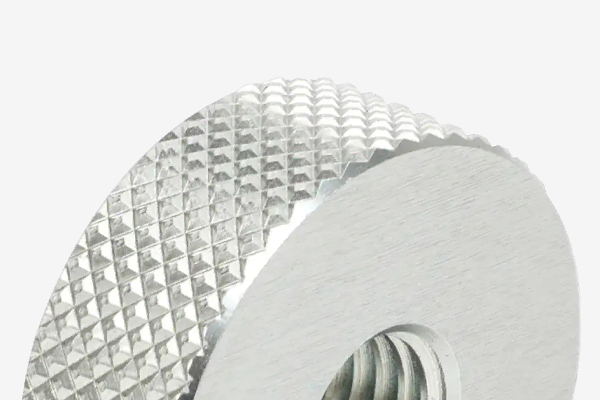

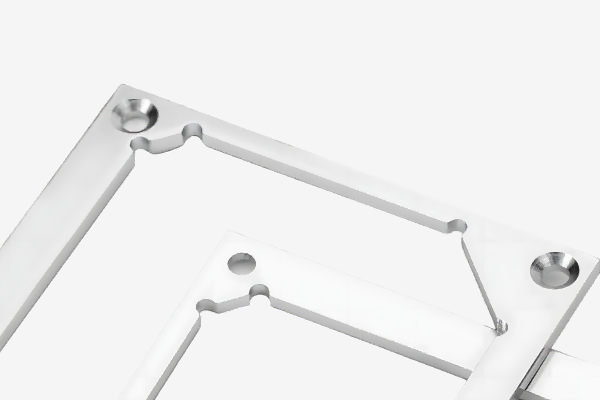

Check out our cases

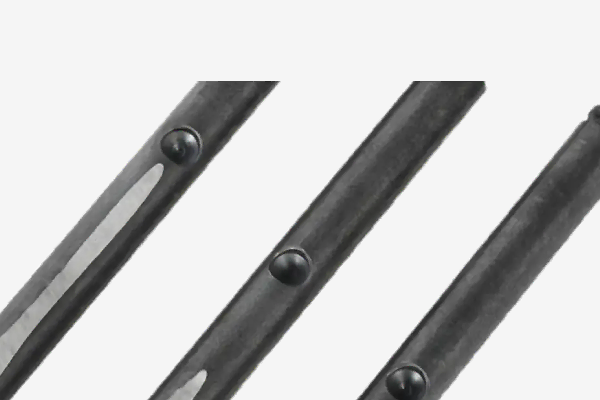

CNC Turning Parts Gallery

Explore our precision-machined components for various industries and discover innovative designs and craftsmanship that might meet your manufacturing needs.

CNC Turning FAQ

FAQs and Solutions

provides CNC machining solutions for a variety of industries. Whether it’s durable consumer products, complex electronics, industrial machinery, or medical devices, we deliver reliable and precise components tailored to your needs.

If you have any questions about the task, please feel free to contact us.

Our experienced engineers will respond to you within 1-24 hours

CNC turning creates cylindrical and symmetrical parts like shafts, pins, rods, and bushings. It’s also used for threading, boreholes, and contours, ensuring tight tolerances and smooth finishes for industries like aerospace and automotive.

Yes, CNC lathes can machine plastics like ABS, Polycarbonate, PTFE, Nylon, and Acetal. Proper cutting speeds and tool selection prevent melting or deformation, ensuring high-precision plastic components.

CNC milling moves a cutting tool across a stationary workpiece, ideal for complex geometries. CNC turning rotates the workpiece while a stationary tool shapes it, making it best for cylindrical parts like shafts and rings.

Common materials include aluminum, stainless steel, brass, titanium, and plastics like Nylon and Acetal, each chosen based on strength, machinability, and application needs.

We offer surface finishes like polishing, anodizing, passivation, and more to improve durability, corrosion resistance, and aesthetics.

CNC turning automates processes with high precision, reduces material waste, and increases production speed, especially for high-volume manufacturing.